In the world of manufacturing and fabrication, precision and efficiency are paramount. One of the key components that contribute to achieving these goals is the use of CNC (Computer Numerical Control) machining hot press plates. These plates play a crucial role in various industries, from aerospace to automotive, and understanding their functionality, benefits, and applications can significantly enhance production processes. This comprehensive overview will delve into what https://www.nuknail.com/CNC-Grinding-Machine-Processing.html are, how they work, their advantages, and their applications across different sectors.

What Are CNC Machining Hot Press Plates?

Functionality

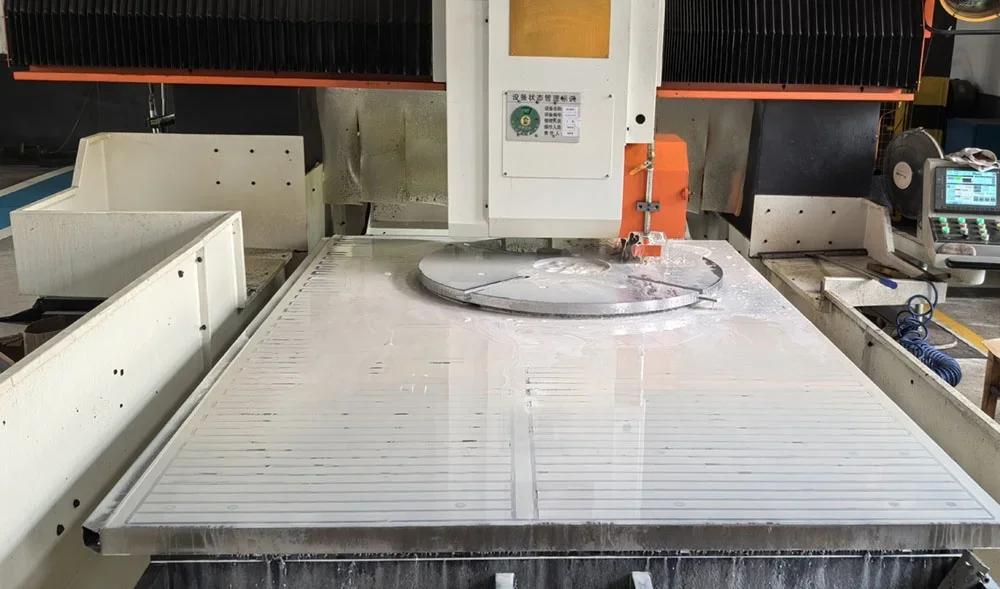

CNC machining hot press plates are specialized tools used in the manufacturing process to apply heat and pressure to materials, typically in the production of composite materials or laminated products. These plates are designed to provide uniform heat distribution and precise pressure application, ensuring that the materials being processed achieve the desired properties and characteristics.

The CNC aspect refers to the automation of the machining process through computer programming. This allows for high precision and repeatability, making it possible to produce complex shapes and designs with minimal human intervention. The integration of CNC technology with hot press plates enhances the efficiency and accuracy of the manufacturing process.

How Hot Press Plates Work

Hot press plates operate by heating the material to a specific temperature while simultaneously applying pressure. The process typically involves the following steps:

1. Material Preparation: The materials to be processed, such as thermoplastics, composites, or wood-based products, are prepared and placed between two hot press plates.

2. Heating: The plates are heated to the required temperature, which is crucial for softening the material and facilitating the bonding process.

3. Pressing: Once the desired temperature is reached, the plates apply pressure to the material. This pressure helps to eliminate air pockets, ensuring a strong bond between layers or components.

4. Cooling: After the pressing cycle, the plates are cooled down, allowing the material to solidify and retain its new shape.

5. Removal: The processed material is then removed from the hot press plates, ready for further machining or finishing.

Advantages of CNC Machining Hot Press Plates

1. Precision and Consistency

One of the advantages of using CNC machining hot press plates is the high level of precision they offer. The CNC technology allows for exact control over the temperature and pressure applied during the process, resulting in consistent quality across batches. This precision is essential in industries where tolerances are critical, such as aerospace and automotive manufacturing.

2. Enhanced Efficiency

CNC machining hot press plates streamline the manufacturing process by reducing the time required for heating, pressing, and cooling. The automation provided by CNC technology minimizes human error and allows for faster production cycles. This efficiency translates to lower operational costs and increased output, making it an attractive option for manufacturers.

3. Versatility in Material Processing

Hot press plates can be used with a wide range of materials, including thermoplastics, thermosetting plastics, composites, and even metals. This versatility makes them suitable for various applications, from producing lightweight components in the aerospace industry to creating durable products in the furniture sector.

4. Improved Material Properties

The combination of heat and pressure applied by hot press plates can enhance the properties of the materials being processed. For instance, the bonding strength of composite materials can be significantly improved, resulting in products that are lighter yet stronger. This enhancement is particularly beneficial in industries where performance is critical.

5. Cost-Effectiveness

While the initial investment in CNC machining hot press plates may be significant, the long-term cost savings can be substantial. The efficiency, precision, and reduced material waste associated with these systems can lead to lower production costs over time. Additionally, the ability to produce high-quality products can enhance a company's reputation and marketability.

Applications of CNC Machining Hot Press Plates

1. Aerospace Industry

In the aerospace sector, weight reduction is a critical factor. CNC machining hot press plates are used to manufacture lightweight composite components that meet stringent safety and performance standards. The ability to create complex shapes with high precision makes these plates invaluable in producing parts for aircraft and spacecraft.

2. Automotive Manufacturing

The automotive industry utilizes CNC machining hot press plates for producing various components, including body panels, interior parts, and structural elements. The enhanced strength and durability of the materials processed with hot press plates contribute to the overall safety and performance of vehicles.

3. Furniture Production

In furniture manufacturing, hot press plates are used to create laminated products, such as countertops and cabinetry. The ability to bond different materials together while achieving a smooth finish is essential for producing high-quality furniture that meets consumer demands.

4. Electronics Industry

CNC machining hot press plates are also employed in the electronics industry for producing circuit boards and other electronic components. The precision and consistency offered by these plates ensure that the delicate components are manufactured to exact specifications, reducing the risk of failure.

5. Renewable Energy

In the renewable energy sector, hot press plates are used to manufacture components for solar panels and wind turbines. The ability to create lightweight yet strong materials is crucial for optimizing the efficiency and performance of renewable energy systems.

Conclusion

CNC machining hot press plates are an essential tool in modern manufacturing, offering a range of benefits that enhance precision, efficiency, and material properties. Their versatility across various industries, from aerospace to furniture production, highlights their importance in meeting the demands of contemporary manufacturing processes.

Liankun was founded in 2006, focusing on the production and research of hot platens for hydraulic press. With "thermal conductive steel platens" as the core product, we have formed five series of products (hot press platens, cold press platens, electric heating platens, mold plates, non-standard plates) and targeted solutions for different industries, scales, and applications worldwide. Liankun is a globally influential hot platen supplier.

Welcome to inquiry if you need to know more about product details or order wholesale.

E-mail:ivy@nuknail.com