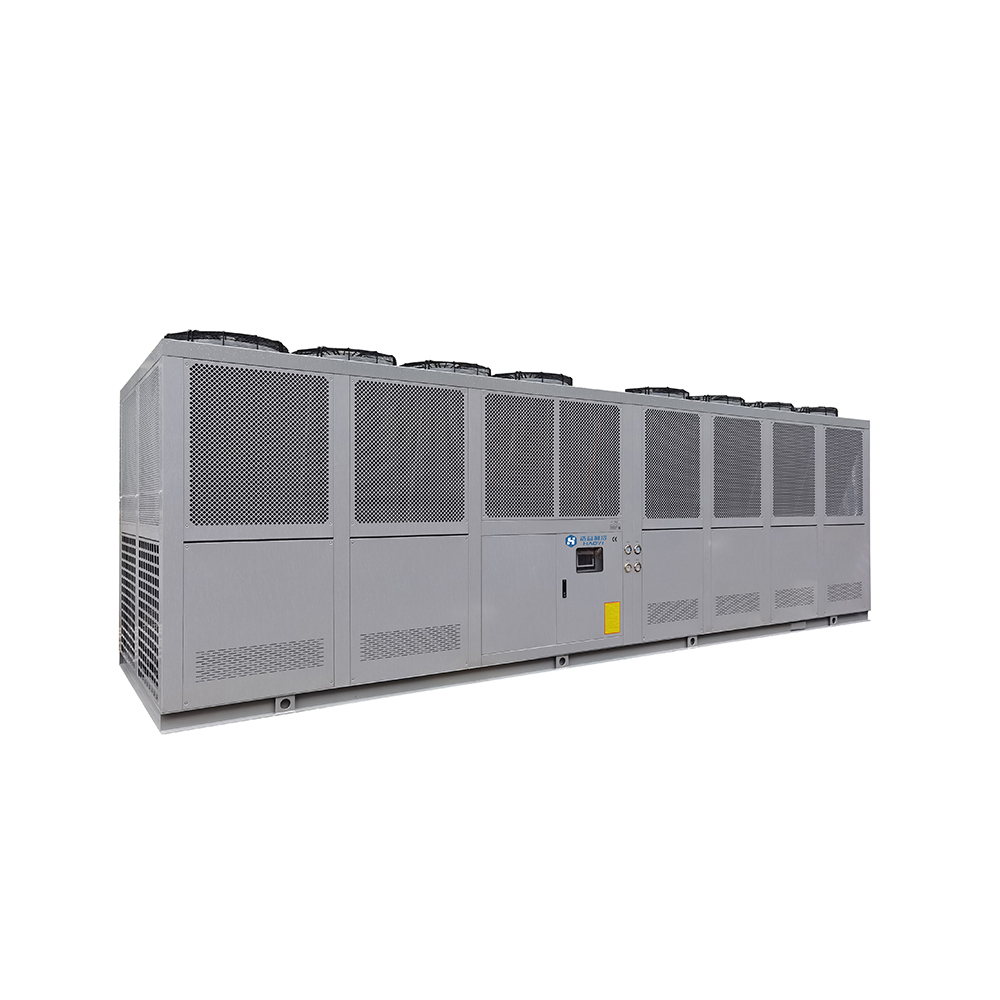

In today’s fast-paced industrial landscape, efficiency, stability, and environmental adaptability are key priorities when choosing cooling systems. Among the many options available, the Air Cooled Screw Chiller stands out as a reliable and energy-efficient solution for various commercial and industrial applications.

What Is an Air Cooled Screw Chiller?

Anhttps://www.szdxzl.cn/HY-AD-Series-Air-cooled-Screw-Chiller-Dual-CompressorsExplosion-proof.html is a type of refrigeration equipment that uses ambient air to remove heat from the refrigerant, without the need for a cooling tower or water source. At its core, the system is driven by a screw-type compressor, which is known for its high stability, smooth operation, and long lifespan.

Unlike water-cooled chillers, air-cooled chillers are easier to install and maintain, making them especially popular in areas with water scarcity or in buildings where cooling tower installation is impractical.

Key Features of the Air Cooled Screw Chiller

1. Efficient Screw Compressor Technology

The screw compressor is the heart of the unit. Compared to traditional piston compressors, screw compressors provide continuous compression with less vibration, lower noise, and improved energy efficiency.

2. No Cooling Tower Required

Since air cooled screw chillers dissipate heat directly through finned coil condensers and axial fans, they eliminate the need for additional infrastructure like cooling towers and water pumps, reducing overall operational costs.

3. Wide Range of Capacities

These chillers are available in a variety of cooling capacities, typically ranging from 30RT to over 500RT, making them suitable for small facilities as well as large-scale manufacturing plants.

4. Easy Installation and Lower Maintenance

With a modular design and fewer supporting systems, installation is more straightforward and maintenance intervals are less frequent compared to water-cooled systems.

5. Environmentally Friendly Options

Modern air cooled screw chillers are compatible with eco-friendly refrigerants such as R134a, R407C, and R513A, supporting businesses’ goals toward sustainability and regulatory compliance.

Common Applications of the Air Cooled Screw Chiller

Air Cooled Screw Chillers are widely used across diverse industries, including:

Plastic Injection & Blow Molding

Pharmaceutical & Chemical Production

Electronics & Semiconductor Manufacturing

HVAC Systems in Commercial Buildings

Food & Beverage Processing

Data Centers & Server Rooms

These systems are particularly ideal for environments that require year-round cooling with minimal system downtime.

Final Thoughts

As industries evolve toward smarter, leaner operations, the Air Cooled Screw Chiller continues to gain popularity due to its performance, convenience, and adaptability. Whether you’re upgrading an existing system or planning for a new facility, investing in a well-designed air cooled chiller can lead to significant long-term benefits in energy savings and operational reliability.

If you're looking to integrate a robust cooling system into your process, consider an Air Cooled Screw Chiller tailored to your specific industrial or commercial needs.

Contact us today to learn more or request a customized cooling solution.

E-mail:info@szdxlh.com

Top 5 Advantages of Using Air Cooled Screw Chillers in Commercial HVAC Systems